Single-shaft Powerful Shredder - MSD-1000 With Conveyor

A single-shaft shredder is an industrial machine used for shredding materials like plastics, wood, metal, and rubber into smaller, manageable pieces. It features a rotor with sharp cutting blades that rotates within a chamber, where material is fed through a hydraulic pusher or gravity. The cutting process occurs between the rotor blades and a stationary counter blade. Its single-shaft design ensures efficient material processing while minimizing energy consumption and mechanical complexity.

WEI SHENG’s MSD-1000 Single Shaft Powerful Shredder features a single cutterhead configuration with multiple knives for superior shredding capacity. Powered by a sturdy motor and gearbox transmission, this shredder delivers exceptional torque. It offers outstanding shredding performance, even for tough materials. The shredded output size can be easily adjusted by selecting different hole sizes on the sieving screen, allowing for customizable results.

By utilizing PLC control, operators have the flexibility to adjust settings to accommodate various materials, improving productivity. The hydraulically operated automatic material infeed allows fast and efficient feeding. This MSD-1000 with Conveyor is great for applications that demand high shredding capacity and material handling operations. WEI SHENG is a professional single-shaft shredder manufacturer in Taiwan. Please do not hesitate to contact us for further details.

Features

- Single cutterhead configuration with multiple knives provides exceptional shredding capacity.

- Powerful motor drive and gearbox transmission deliver excellent torque, resulting in impressive shredding capacity.

- The shred size can be adjusted based on the size of the sieving screen holes.

- Fast knife replacement for added convenience and time-saving.

- The hydraulic power unit is equipped with a water cooling device, allowing the hydraulic system to operate at a constant temperature.

- The cutterhead is equipped with a water cooling device to effectively reduce the thermal deformation of the cutterhead.

- The PLC control allows for adjustments to be made to accommodate various materials.

- Hydraulically operated automatic material infeed enables fast and efficient input, increasing productivity.

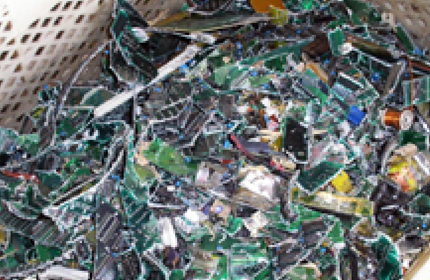

Shredding Samples

Specifications

| Model | Motor (HP) | Inlet Dimn. (mm) | Rotating Knife No. | Fixed Knife No. | Working capacity |

|---|---|---|---|---|---|

| MSD-700 | 40~50 | 700 x 650 | 39/52 | 4 |

Working capacity is dependent on material types and hole size of sieving screen. |

| MSD-1000 | 60~75 | 1000 x 650 | 60/80 | 6 | |

| MSD-1350 | 75~100 | 1350 x 1000 | 81/108 | 8 | |

| MSD-1700 | 125~150 | 1700 x 1000 | 102/136 | 10 | |

| MSD-2000 | 100 x 2 | 2000 x 1500 | 123/164 | 12 | |

| MSD-2500 | 125 x 2 | 2500 x 1500 | 153/204 | 14 | |

| MSD-3000 | 150 x2 | 3000 x 1500 | 186/248 | 18 |

* The above speciations subject to change without prior notice.